"dieseldub" (dieseldub)

"dieseldub" (dieseldub)

03/05/2019 at 12:11 ē Filed to: None

25

25

45

45

"dieseldub" (dieseldub)

"dieseldub" (dieseldub)

03/05/2019 at 12:11 ē Filed to: None |  25 25

|  45 45 |

Many months ago, I wrote about how I probably !!!error: Indecipherable SUB-paragraph formatting!!! for buying a Touareg V10. Granted, I bought it for cheap already knowing what level of work would be needed to make it right again.

Well, I ordered a set of camshafts from a company in Canada, and FedEx lost them... Itís taken a lot of time to go through their claims system to try and get it resolved, and they only paid about 10% of what I actually paid for the cams. So, eventually Iíll have to try my hand at small claims.

I got tired of waiting to get my money back to buy again, so I went ahead and ordered another set, theyíve now shown up and Iím starting the work.

The w hole drivetrain is out. The engine, transmission, transfer case, front axle, front prop shaft, steering rack, front sub frame and most of the front suspension and brakes come down as one assembly. The two 60 pin connectors (one on each ECU, the ECUsóyes, pluralóalso have a second 94 pin connector that stays with the body side) come off the two engine computers and the vast majority of the wiring harness for the engine comes out with it, a few connectors also had to be undone at the ebox on the driver side next to the wiper motor. The two glow plug wiring harnesses are wired into the body harness and get disconnected separately. MAF wiring also stays with the body, a coolant temp, AC pressure sensor and some kind of valve or sensor on the steering rack had to be unplugged as well. Overall, undoing the wiring was the easy part.

Undo a few vacuum hoses, a number of coolant hoses to the radiator, and auxiliary radiator and the heater core have to be undone, and the ones at the front/lower section of the truck arenít the easiest to undo. AC had to be discharged and a couple hoses disconnected. Trans cooler lines too, shift linkage at the transmission. Rear exhaust removed, rear driveshaft too.

All told, with me taking my time, it took about 10 hours just to drop the assembly.

And now with it on the ground, time to get into the reason why I removed it.

First, weíll start with what a normal cam valve lobe is supposed to look like on a VW pumpe duse TDI engine. Notice the chamfer all the way around the edges of the lobe. When these start to wear, that small chamfer will be the first thing you notice as being gone at the apex of the lobe, and the edges mushroom over a little and become a sharp edge.

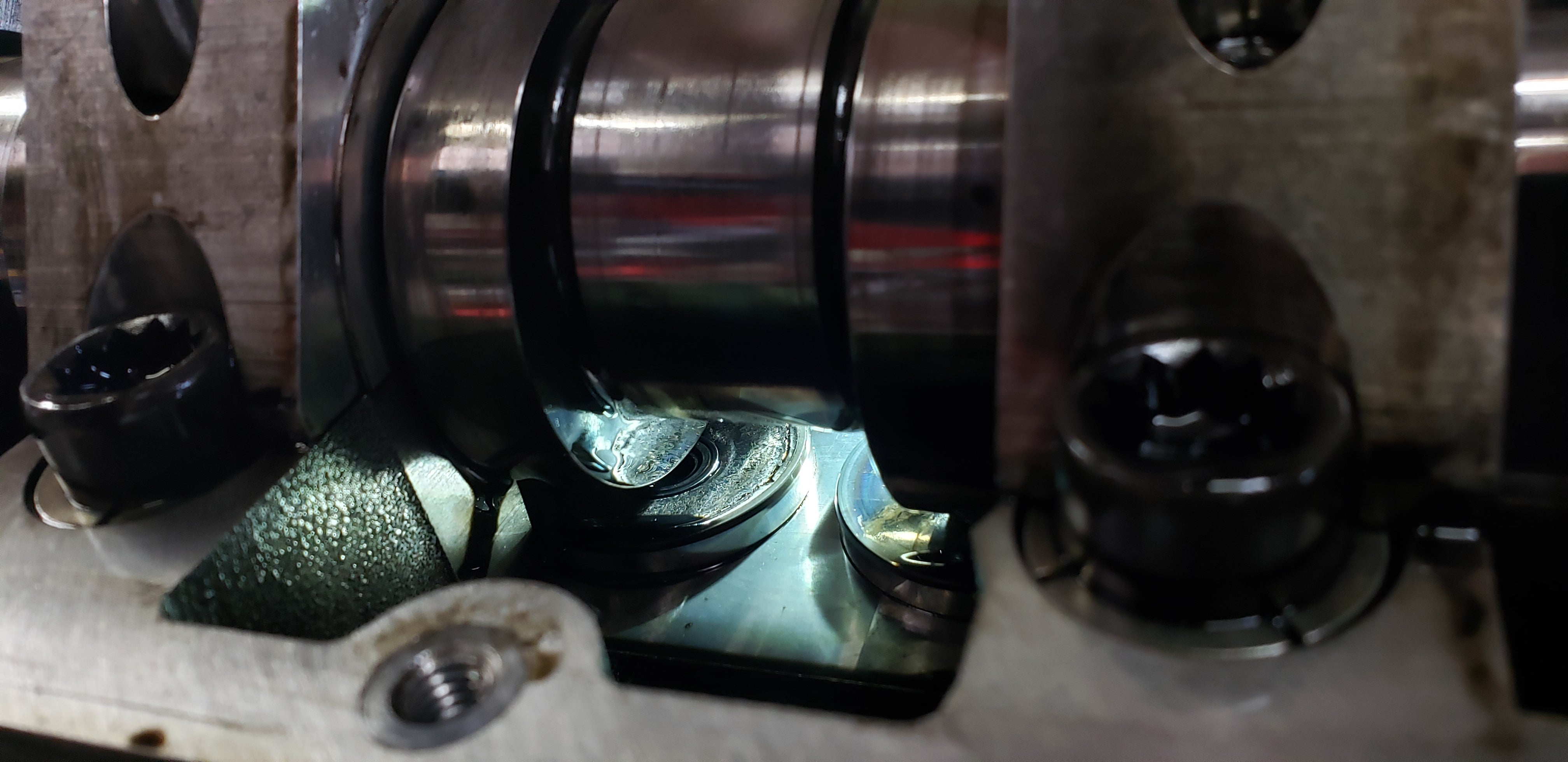

What one of the lobes on bank 2 looks like:

Iíve seen many worn PD cam lobes before. Itís an unfortunate engineering failure on VWís part on this particular style TDI engine. The 4 cylinders we got here in the U.S. from 2004-2006 are just as prone to this sort of thing. Unfortunately, the big bad, expensive V10 was not spared from this engineering oversight. This one lobe just might be the most worn/flattest Iíve ever seen in a PD, though. And Iíve seen numerous 4 cylinders that have worn holes into the lifters... Speaking of, hereís a photo of the corresponding lifter underneath:

Nice, large dish worn into it and a hole. The lifter next to it? Perfectly flat.

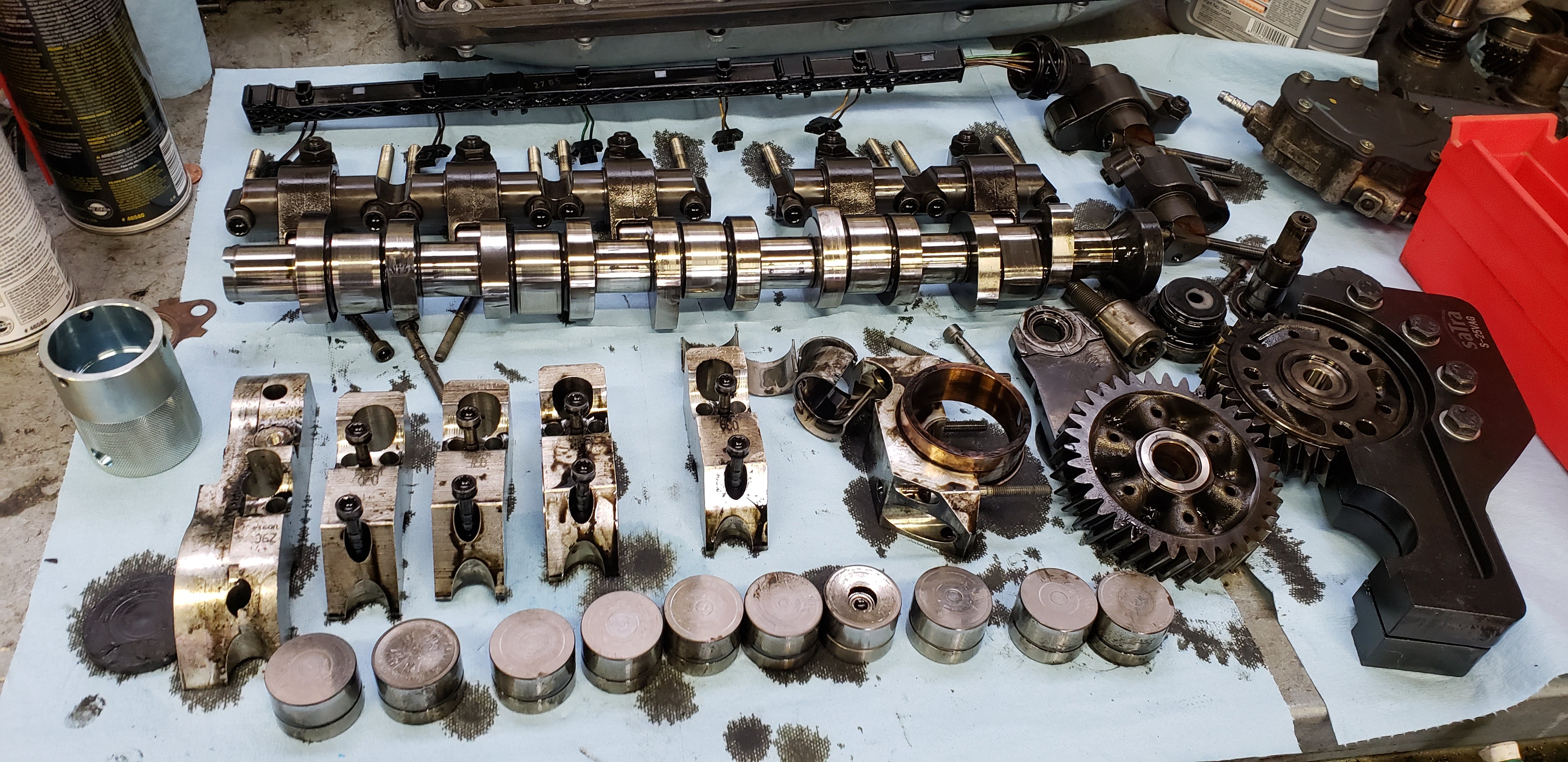

The cool thing about this engine, which also makes valvetrain work expensive and time consuming? The cams are gear driven on the V10. The 4 cylinder diesels all use a timing belt. In fact, thereís not a belt anywhere on these V10s, not even for accessories. Everything is gear driven or is coupled to another accessory that is gear driven.

Hereís bank 2's cam, lifters, cam caps and gears on the bench:

You can see one of the lifters on the left part of the screen was starting to dish out and wear as well, as was its corresponding cam lobe.

While Iím in the engine this deep, knowing what I do about PD TDIs, might as well do injector seals too while Iím in it this far:

The other issue it had is bank 2's turboís external rod linkage corroded to the point of preventing the full range of movement of that turboís actuator/control module, and thus vane mechanism. This actually caused the truck to immediately set a ďturbo control module defectiveĒ upon turning the key on. This is because the control module does a check every time itís keyed on, it goes to its min and max positions real quick to make sure everything is OK. And when the module is physically prevent from going through its full range of motion, it sets that code.

This leads people to believe the turbo control module is, well, defective. Because thatís what the code said, right? Well, before I removed the engine, I did a test. I popped the linkage off bank 2's turbo control module (the one that was setting the code) and attempted to see if I could move that turboís vane mechanism by hand, and when I realized it was physically impossible to do at the angle it was mounted at, I decided to key it on, clear the codes, key it on and off a couple more times, allowing the turbo modules to go through their self checks of min and max position each time, and then recheck for codes. Guess what? The turbo control module defective code didnít come back so long as the linkage was removed from the control module, thus allowing the module to be able to move through its full range of motion.

So, while itís out and I confirmed the vane mechanism internally in the turbo moves freely, I removed both linkages, sanded the rust off each arm and used a small ďgrinding stoneĒ in my dremel kit (the stuff is softer than the steel the rods are made of, so minimal removal of metal will happen, but works great to remove the corrosion) to remove the corrosion from inside the arms. Used some high temp synthetic caliper grease slathered all over inside those pivot points, reassembled, and then slathered some more on the outside in an effort to prevent the corrosion from happening again.

I think every oil change I will peek up there and make sure the grease still looks OK, and reapply as needed. Iím curious to see how long the stock turbos can go, and prove people wrong that these are not actually fragile junk. Itís just a small amount of preventative work that should in theory stave off the dreaded turbo control module defective codes once you understand the most common way that code sets is merely an external linkage corrosion issue.

And with that, back at it. I have to install the new cam on this bank, and then tear down bank 2 and do the same. Hoping that by the end of the week Iíll be driving it, get all the readiness monitors to set, go get it titled and plated in my name and enjoy.

MasterMario - Keeper of the V8s

> dieseldub

MasterMario - Keeper of the V8s

> dieseldub

03/05/2019 at 12:52 |

|

I need a lift...things look so much easier with them. I assume that would be a 40 hour job to remove the drivetrain if one did not have access to a lift.

I love those V10 diesels in theory and I never knew they had gear driven cams and accessories, thatís really cool.

dieseldub

> MasterMario - Keeper of the V8s

dieseldub

> MasterMario - Keeper of the V8s

03/05/2019 at 12:58 |

|

Things are indeed much easier with them. Without it for this job, youíd probably need a pallet and pallet jack and remove the entire front end of the truck. And have fun getting the rear exhaust and driveshaft off without being able to lift the truck very high...

I used to do that sort of thing for years when I tried my hand at being a mobile mechanic, but there are some jobs that are just not very easy to do without a hoist.

functionoverfashion

> dieseldub

functionoverfashion

> dieseldub

03/05/2019 at 13:01 |

|

This is amazing. I remember seeing one of those back in 2004 (I think??) and not realizing what kinds of maintenance headaches were involved. I really wanted one.

I still kind of do, but without your kind of ability and shop space, itís probably financially ruinous.

Are you trained in VW stuff or is this just some high-class tinkering plus interwebs?

That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

> dieseldub

That Bastard Kurtis - An Attempt to Standardize My Username Across Platforms

> dieseldub

03/05/2019 at 13:09 |

|

I wasnít aware there was TDI Tourareg stuff happening on Oppo, but I think this just became the project on here Iím most interested in. Great write up.†

BobintheMtns

> dieseldub

BobintheMtns

> dieseldub

03/05/2019 at 13:12 |

|

That cam lifter.. wow.

Very cool write-up. And very cool project

DipodomysDeserti

> dieseldub

DipodomysDeserti

> dieseldub

03/05/2019 at 13:12 |

|

ď Iím curious to see how long the stock turbos can go, and prove people wrong that these are not actually fragile junk.Ē

Well, they did outlast the cams, which something that can really only happen in something made by VW.

For Sweden

> dieseldub

For Sweden

> dieseldub

03/05/2019 at 13:17 |

|

I am both terrified and aroused

dieseldub

> functionoverfashion

dieseldub

> functionoverfashion

03/05/2019 at 13:24 |

|

I trained myself on all things TDI from when I got my first one back in 2004. Lots of internet readings, lots of trial and error, using VWís official repair manuals, and I did try to hang my own shingle out as a mobile mechanic specializing in TDIs for a few years, then deciding that while interesting and fun, it wasnít conducive to making an adequate paycheck just with the time and expenses of being on the road. So, I decided to try working for a dealer, which also would help me get caught up on the latest and greatest tech a few years ago.

That lasted about a year before I couldnít take the feeling of being screwed from every angle, just like when I worked in a tire shop in Michigan doing wheel alignments and suspension work for a few years. So, back to hanging out my own shingle, but this time with shop space. Just sub-leasing a bay from an existing shop where the guy who owns the place simply doesnít want to employ anyone anymore and would rather sublease a bay out and split rent. To his credit, it is hard to find genuinely knowledgeable, competent techs these days, which is why Iíll likely do whatever it takes to remain a one man operation. I trust no one with my own cars, and thus have a hard time trusting someone else with my reputation working on a customerís car.

So, short answer, a bit of both. I am a technician by trade, but tinkering with my own stuff is how I became comfortable doing the big, crazy jobs in the first place. Going to school to be trained only gets you so far, but at the end of the day, if you arenít getting your hands on the stuff yourself and just figuring it out along the way, you probably never will really understand or develop the feel for how to do many aspects of such jobs. Though having a good reading comprehension when reading repair manuals and a never quit attitude also will take you far... That and knowing what special tools you should just buy and what ones you can get away with making your own. And there are a lot of special tools in a vehicle like this.

I donít have a lot of Touareg or V10 experience. I did do turbos on one for a customer last year, so itís at least not my first rodeo in RRing one of these, but itís still quite a lot different than the transverse mount 4 cylinders I normally work on. This is definitely going to be more of a toy for me rather than something to be relied on as a daily driver. Anytime something goes wrong on it, it can be costly and time consuming to fix, and I might not always have the money to throw at it. Plus, the fuel consumption alone just makes it less than practical as a daily driver... at least to me, since Iím going on 15 years of being used to getting over 40 MPG average with most of my cars. heh

dieseldub

> dieseldub

dieseldub

> dieseldub

03/05/2019 at 13:29 |

|

Oh, speaking of special tools, youíll notice one of the special tools Iím doing without on this project is VWís $10,000 (with adapters) engine table.

I just dropped the sucker on jack stands and lifted the truck off it. If I were splitting the engine and transmission, Iíd have to rethink it, but since Iím just doing top end work, this is more than adequate. As nice as that engine table is, I donít have the space or extra funds for that kind of equipment.

Once I began looking at the costs of all the tools and equipment dealers are REQUIRED to buy from the manufacturer, I started to understand why they charge as much as they do. Some of us indie guys make do with less and get creative for some of the less-than-absolutely-necessary tools and equipment, but thatís how we can afford to charge less of course.

Brickman

> dieseldub

Brickman

> dieseldub

03/05/2019 at 13:39 |

|

The engine is backwards? How you change the belt.... remove engine :P

or is there a belt? German engineers sure make some strange stuff.

Daily Drives a Dragon - One Last Lap

> Brickman

Daily Drives a Dragon - One Last Lap

> Brickman

03/05/2019 at 13:45 |

|

I am also confused. Looking at some cutaways, the torque converter, transmission and transfer case look pretty standard and it's all on the back of the engine. So then why is this on the front?†

dieseldub

> Brickman

dieseldub

> Brickman

03/05/2019 at 13:59 |

|

No belts at all on these.

The powersteering pump is hiding underneath bank 2's turbo (which is the side visible in the side shot of the entire drivetrain). Itís driven off the gear stack which is on the transmission side of this engine. The AC compressor has a goofy coupler and is driven off the backside of the power steering pump.

The alternator resides in the engineís V, underneath the fuel filter among other things, and is water cooled and uses a similar coupler that the AC compressor to powersteering uses... and itís to what is effectively a 2 speed gearbox for the alternator.

So, it would appear VW was attempting to make this a vehicle that would require minimal servicing, so long as the alternator, powersteering pump, AC compressor etc donít fail themselves, they have no belt to worry about replacing. And the cams are gear driven as well, so no chain or belt to worry about stretching or have a tensioner fail.

dieseldub

> Brickman

dieseldub

> Brickman

03/05/2019 at 14:00 |

|

But yeah, the big flywheel/balancer on the front of the engine is definitely odd. No belt pullies hook to it, itís just a big ol flywheel, spinning away on the front of the engine.

EDIT: I assume these engines need some sort of balancing like this as V10s arenít a configuration that balances naturally. Flat 6s and V12s are the only ones that seem to do that really well without much extra help.

random001

> dieseldub

random001

> dieseldub

03/05/2019 at 14:23 |

|

Well, I know wh

o to come to when I buy one of these.

benjrblant

> For Sweden

benjrblant

> For Sweden

03/05/2019 at 14:24 |

|

terraroused? arouified?

dieseldub

> random001

dieseldub

> random001

03/05/2019 at 14:34 |

|

I like how you said ďwhenĒ in that sentence. Like itís a foregone conclusion.

Itís still an absurdly time consuming and expensive vehicle to fix even at cost on parts . Then paying someone labor on top of that... just ouch. Takes some planning to try and ensure the job goes smoothly and thereís so many other things it might need that you simply could not see before you take the drivetrain out... then special order parts and wait... and wait some more. Wish I had a second hoist whenever that happens.

Really neat vehicles, though. What better vehicle for the ultimate TDI nerd than the ultimate TDI* (*sold in North America), right?

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> dieseldub

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> dieseldub

03/05/2019 at 14:47 |

|

Hah! Iím about to do a timing cover and timing plate gasket on my 1995 Ford 1720 compact tractor, the water pump/fan and alternator are driven by a single belt on that little 3cyl Shibaura engine, and everything else is gear driven. You have to remove the power steering pump, hydraulic pump, limiter drive, injection pump linkage, oil pump drive, cam idler gear, and balance-shaft drive to replace a pair of $12 gaskets. This means you have to also pull the front sheet metal/grill/hood , radiator, intake runner, injector lines , battery tray, and some people like to remove the front axle too, as it gives more room to pull the entire front of the engine apart. Wanna come help me with that job after you finish the Toua reg? Book time is only 20-24 hours on my job.

DL

> dieseldub

DL

> dieseldub

03/05/2019 at 15:44 |

|

I have my 2006 V10 in the shop right now - cams were changed last summer to little avail and now it may mean weíll need to pull the heads to get deeper into the repair. I have two turbos on my shelf at home that could use a rebuild after being swapped out, a vacuum/oil pump that was leaking oil onto the exhaust which will hopefully just need a rebuild, my old camshafts (my lobes werenít NEARLY as bad as that one) and one injector (which are going for about $1,000 each right now...so Iím thinking Iíll rebuild them one-by-one and swap them out as needed).

Iíve had the ECUs replaced because there was apparently faulty comms between them (I should have eaten the core charge on those and kept them as well with the idea I probably could have repaired them myself).

Itís been my wifeís driver, and she simultaneously wants to set it out to pasture and cling to it because she canít enjoy driving anything else. I donít know if they all came with the adjustable ride system, but winter wouldnít driving isnít the same without it.

Best of luck with yours!

VincentMalamute-Kim

> dieseldub

VincentMalamute-Kim

> dieseldub

03/05/2019 at 16:40 |

|

Thanks for teaching.

Saracen

> dieseldub

Saracen

> dieseldub

03/05/2019 at 16:48 |

|

The TDI V10 does indeed have a balance shaft.

Straight 6's are perfectly balanced, which is why V12's are too.

Darkbrador

> dieseldub

Darkbrador

> dieseldub

03/05/2019 at 17:12 |

|

Jeeeez .... youíll have deserved to enjoy that sweet diesel V10 ... Iím impressed.

Sampsonite24-Earth's Least Likeliest Hero

> dieseldub

Sampsonite24-Earth's Least Likeliest Hero

> dieseldub

03/05/2019 at 17:24 |

|

so what youre saying is to wait till youre done with it then buy it from you? lol

dieseldub

> Sampsonite24-Earth's Least Likeliest Hero

dieseldub

> Sampsonite24-Earth's Least Likeliest Hero

03/05/2019 at 19:25 |

|

Haha! Sure, why not??

No promises it wonít require another engine-out procedure at some point... Need an AC compressor? Remove engine. Power steering pump? Remove engine. Starter? Remove engine.

Just how it works on this thing. But you can replace glow plugs and alternator while itís installed in the truck, so thereís that. Doing either requires removal of both intakes, though, among other things. heh

functionoverfashion

> dieseldub

functionoverfashion

> dieseldub

03/05/2019 at 21:10 |

|

This makes a lot of sense. I totally agree that thereís no substitute for doing the actual work with stuff like this. Iíve watched videos and read threads on forums, in addition to reading a repair manual procedure on things before. And still, nothing can prepare you for the actual work like experience. How do you keep that washer on there while also getting that bolt in place without dropping the piece youíre trying to hold and then get a wrench on it, all on some part you canít see? What are you going to have to remove just because you donít have a tool that fits in THAT particular space or just so you can get enough leverage to remove a rusty bolt? Itís endless.

And I canít wait to see another update on this rig.

functionoverfashion

> dieseldub

functionoverfashion

> dieseldub

03/05/2019 at 21:14 |

|

I did notice you seemed to take a reverse approach to the drivetrain ďdropĒ but hey, it works.

I worked at a marina for a while and got to see some of the crazy requirements from OEMs on what we needed for tools. On paper, anyway, each separate manufacturer would require us to have a specific slide hammer. Or something like that. But the one we had from 1977 that had 15 adapters either that came with it or that were custom-made over time... it worked for everything. Pullers, presses, torque wrenches. We would have gone bankrupt trying to outfit the shop if the manufacturers had been sticklers about it. Then thereís computer interfaces and software with no standardization in the marine industry. I totally get why ďdealersĒ have to charge more money for labor than independent shops.

random001

> dieseldub

random001

> dieseldub

03/05/2019 at 21:23 |

|

Heh.† Always plan for the future.

eddo

> dieseldub

eddo

> dieseldub

03/06/2019 at 06:37 |

|

So, Iíve got one of these beasts, all works great except!

1. O2 sensor error consistently pops up every so often

2. Suspension recently replaced, has some ... Inconsistencies that could be simple fixes but no other mechanic can figure out

3. Battery drains every 2 weeks, unless driven.

Would love to know what youíd charge to do a full mechanical teardown under chassis, inspection, steam clean and rebuild.

Buddybilt

> dieseldub

Buddybilt

> dieseldub

03/06/2019 at 08:44 |

|

I donít think youíre crazy at all. I had one of these back in 2015 that both my wife and I LOVED! She liked it because it wasnít too big for her and I liked it because it had ďAll the powerĒ it was fun to drive. But also comfortable for road trips. Plus even though it wasnít rated for it. I used it on more than one occasion to haul cars that had broken down. The heaviest load I ever put behind it was my brother in-law's Yukon XL. Which I hauled back to Minneapolis from about Green Bay Wisconsin. It handled it as if it was nothing more than a snowmobile. We actually regret greatly selling it. But I started a business and we needed the capital to setup the business.†

dieseldub

> Buddybilt

dieseldub

> Buddybilt

03/06/2019 at 11:17 |

|

The hitch that came with mine says itís rated for 7700 lbs. Should do the trick just fine!

That is definitely one of the reasons I wanted it, the tow capacity and the ease of which it can tow. I want to be able to haul broken cars when necessary.†

dieseldub

> eddo

dieseldub

> eddo

03/06/2019 at 11:53 |

|

Iíll start with this: step one of replacing O2 sensors on this engine? Engine removal. Now, on a PD engine, the O2 sensor is only really there to help keep track of how well the EGR system is working and using the old school method of MAF readings as a back up. That having been said, a good TDI tuner can, umm, make it so those devices are no longer necessary. Would be a cheaper solution, anyway. Not that I condone deleting emissions devices, especially where I do business (California).

I did spend 6 years in a tire shop, 5 of which were largely just doing wheel alignments and suspension work. If you did bring it to me, youíll have to get pretty specific with your suspension concerns so I can try and pinpoint the issue to get it resolved.

These do drain the battery faster than the average VW. The batteries are also quite large and should have ample reserve capacity to offset that a little. VW has specs for what their max allowed parasitic draw is and due to the extra systems and complexities of the early Touaregs and Phaetons, theyíre allowed upto 50 mA draw to be considered acceptable, and mine hovers right at that range. The rest of VWís line up is allowed 30 mA and most draw half that when everything is fine (15 mA).

The V10 does have two batteries, but annoyingly, the auxiliary battery in the back doesnít actually help with starting the truck when the primary battery starts to get a little low.

Itís also possible your battery is now just too depleted from being allowed to get too low and has a far smaller reserve capacity than a fresh battery would. But I can confirm there are things in these trucks that keep on running in the background long after the key is off. The air suspension being one of them. I went to put a jump pack on mine with a dead battery once, without even turning the key on, the air suspension pumped itself up the moment I put the jump pack on the jumper posts. That system seems like itís always monitoring and adjusting, even when the truck is off, at least for a little while.

dieseldub

> dieseldub

dieseldub

> dieseldub

03/06/2019 at 11:54 |

|

Over 3K views in 24 hours! Definitely wasnít expecting that. Makes me wonder if it got linked to on a forum somewhere or social media.

V10tdi

> dieseldub

V10tdi

> dieseldub

03/06/2019 at 18:28 |

|

Quick note. If your starting battery gets low place the key in the ignition and turn it to the left for a few seconds then turn to the right and it will utilize the second battery.

dieseldub

> V10tdi

dieseldub

> V10tdi

03/06/2019 at 19:09 |

|

Hey, now thereís an awesomely useful tip I hadnít heard yet!

Thank you.

Steve

> dieseldub

Steve

> dieseldub

03/06/2019 at 20:53 |

|

You have to understand driving conditions in Germany where the car may be driving flat out for extended periods. The gear system was to eliminate the risks involved with belts and chains. This engine was a feat of engineering but let down by the injection system which was not perfected. Then there were the electronic problems. I had a Phaeton with this engine. A tremendous car but no longer viable with the emission restrictions.

Zac.

> dieseldub

Zac.

> dieseldub

03/06/2019 at 21:41 |

|

I had a 05 4.2. Loved it, tranny gave out at exactly 200k miles. Going to buy another soon! They are money pits, but the drive is worth it.

dieseldub

> Steve

dieseldub

> Steve

03/06/2019 at 22:04 |

|

Interesting comment on the injection system. I tend to find PD systems overall to be pretty reliable. The tandem pumps will leak eventually, but thatís not too bad to deal with. As they get way up there in age and miles, the injector seals can give you issues as well, but on the whole, the PD fuel system can take poor quality fuel far better than the newer commonrail stuff can.

Belts I generally like. They deal with harsh vibrations better than chains and so long as you change them and all the related components at the rated interval, youíll get incredibly reliable, long term service out of it. Chains can jump time without warning. Sometimes you only go 30,000 miles, sometimes you go 150,000-200,000, but especially with an OHC engine, they definitely donít last forever.

I suspect the gear driven setup was made that way because of the packaging of this engine. They effectively wanted to make it as maintenance-free as possible since any job on it would be exceedingly difficult. No vehicle they make has the extra space available to put the accessories in an easily accessible and serviceable position on an engine this size. Plus, itís a very German ďweíre doing this because we can, itís an exercise of our engineering might.Ē

But yeah, electrical problems are part and parcel with an early production, high end German car. Iím sure Iíll find out just how bad it gets eventually. KESSY/ESCL modules seem to be a weak point on these.

dieseldub

> Zac.

dieseldub

> Zac.

03/06/2019 at 22:05 |

|

Really, at 200k, no automatic transmission owes anybody a thing. And if you catch odd shifting behavior soon enough and replace the valve body, these Aisin transmissions tend to just keep on going.

Though I suppose if there were one engine that could test the limits of durability of a beefy Aisin autobox, it would be the V10 torquemeister. lol

NotUnlessRoundIsFunny

> dieseldub

NotUnlessRoundIsFunny

> dieseldub

03/07/2019 at 00:57 |

|

Wow! You are my new hero.

Thanks for writing this up. Much respect for taking on this repair.

VWhy

> dieseldub

VWhy

> dieseldub

03/12/2019 at 07:38 |

|

I recently made a similar purchase of a Cayenne Turbo for cheap. It has quite a few issues which I am chipping away at. T he biggest of which is oil in the coolant...

(Please be the oil cooler)

Working on these overly complex things is fun to do when you have a lift,† have a daily driver and do not have to explain to a customer how 3 other things broke when you were fixing the original problem . Kudos to you for doing it full time!

Nauraushaun

> dieseldub

Nauraushaun

> dieseldub

03/14/2019 at 04:54 |

|

This is so great. Can't wait to read more please don't stop. Fascinating car

dieseldub

> Nauraushaun

dieseldub

> Nauraushaun

03/14/2019 at 14:21 |

|

More on the way soon, trying to find the time to make a post and organize photos/videos.

Iíve been driving it all week and it has passed smog. Working on California DMV legalities now. Almost had it regíd and plated, but itís missing its catalyst sticker under hood so the DMV rep would not complete the VIN verification for an out of state vehicle.

Nauraushaun

> dieseldub

Nauraushaun

> dieseldub

03/14/2019 at 15:51 |

|

so itís FIXED!

Haha, the catalyst sticker . Obv the hardest part about owning and maintaining a V10 TDI.

Why such corrosion? Do such mechanical bits usually corrode? Has it had an unusually harsh life? Is snow a factor?

dieseldub

> Nauraushaun

dieseldub

> Nauraushaun

03/14/2019 at 20:24 |

|

It came from the wrong side of the Rockies. It was in Virginia before I got it, but did do a number of trips to the Northeast and Mid West (Michiganówhere I grew up). The salt they put on the road in most of those states when it snows does a real number on vehicles.

Being in California, I definitely have become spoiled by the fact I can work on 20 year old cars and the corrosion is so minimal itís like it was put together yesterday in some cases. But it also doesnít rain here for 8 months at a time and for those 8 months, the humidity is usually crazy low as well.

Very different story East of the Rockies, thatís for sure! Especially where it snows regularly. Not only does the road salt do it, but the cold also makes moisture in the air condense on cold metal parts that are just sitting.

Nauraushaun

> dieseldub

Nauraushaun

> dieseldub

03/14/2019 at 21:43 |

|

Haha you think youíre spoiled! Iíve never seen snow in Australia and Iíve never seen serious rust on a car. Iíve never owned a car newer than 1994, Iím spoiled as it gets.

V10tdi

> dieseldub

V10tdi

> dieseldub

05/24/2019 at 22:39 |

|

Glad to hear you got the beast running again! Would you consider renting out the tim ing tools? I purchased a set from Europe and the quality is terrible. The crankshaft lock is about 1/2" too short to insert the pin and I can only insert one cam lock at a time so something is definitely off there as well . I havenít opened the engine up yet so I am not sure about the clamps but I am not overly optimistic given the quality of the other tools. †